You are letting terms confuse you.

Bulk/Absorb = CC/CV Mode

Float = CC/CV Mode.

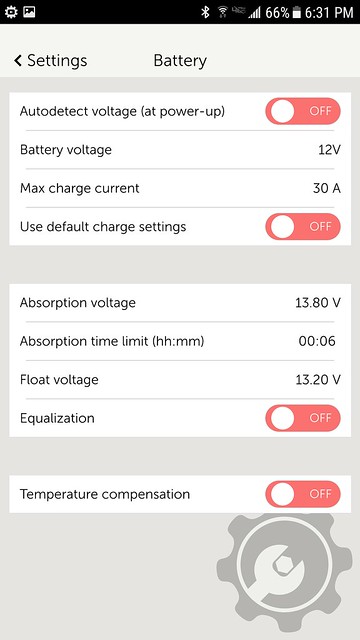

Your charger is nothing more or less than a CC/CV mode charger. The only thing that changes is voltage set points. All you want to do is find the float voltage to get your batteries to 80 to 90% SOC and get rid of the BMS, Assuming you are operating at 12 volts is going to be roughly 13.6 volts. To turn your controller into pure CC/CV is set Bulk = Absorb = Float = 13.6 volts.

If your BMS pulls ,8 amps is going to be the destroyer of your batteries. That means you are burning 250 watt hours a day as waste heat for nothing. Elite BMS systems are notorious LFP battery killers. Get rid of it, you have no need for it.

FWIW to fully charge your batteries requires you to CC/CV at 14.4 volts and hold until the last cell charge current tapers down to 5% of C or 10 amps. So please explain how you will ever know when or if that happens if you are charging at 10 amps? Here is the problem, those Vampire Boards you got from Elite Power only bypass .3 to .5 amps when they turn on at 3.55 volts. That means you still have 9.5 to 9.7 amps flowing into fully charged cells. Your charger is not capable of controlling current when the first Vampire Board turns On to limit current to .3 amps. There is absolutely no reason to take your cells to 100% or even get close to 100%. All you are doing is cutting cycle life in half or more. Cut it to 80 to 90% and you can double to quadruple cell cycle life. Listen to Karak and you will kill your cells.

As for what voltage you see during charging is a function of Charge Current and battery Internal Resistance. If Karrak really knew what he was talking about would know his cells are done. He cannot tell by looking at the graph his cell Internal Resistance has more than doubled in the one cell he is showing. He is looking at 3.25 Milli-Ohms in the graph. Hang around and I will teach you how to do that. Once you know the Ri of a cell, you can keep track of it and know when you have a problem. Karrak has a huge problem and does not know it. Keep in mind Karrak has been banned TWICE FOR POOR AND DANGEROUS ADVICE. So be careful.

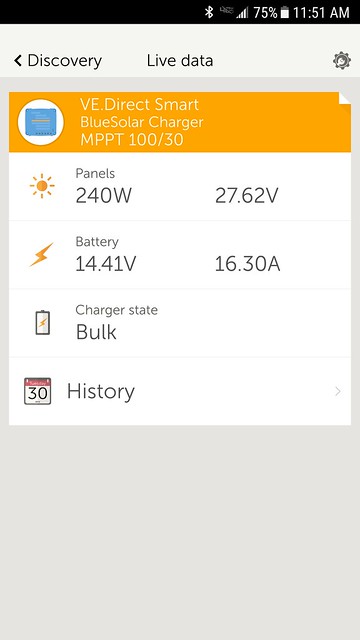

FWIW if your batteries were at 14.41 volts with 16 amps, you were severely over charging your batteries. Stop doing that. Lastly you cannot compare charging a Winston cell to a GBS Cell. They are not the same chemical makeup. Winston is LiFeYPO4 and GBS is LiFePO4.

Try our solar cost and savings calculator

Does my MPPT SCC and 120V charger choice make sense for my LiFeMnPO4 batteries?

Collapse

X

-

Last edited by Sunking; 06-18-2017, 11:11 PM. -

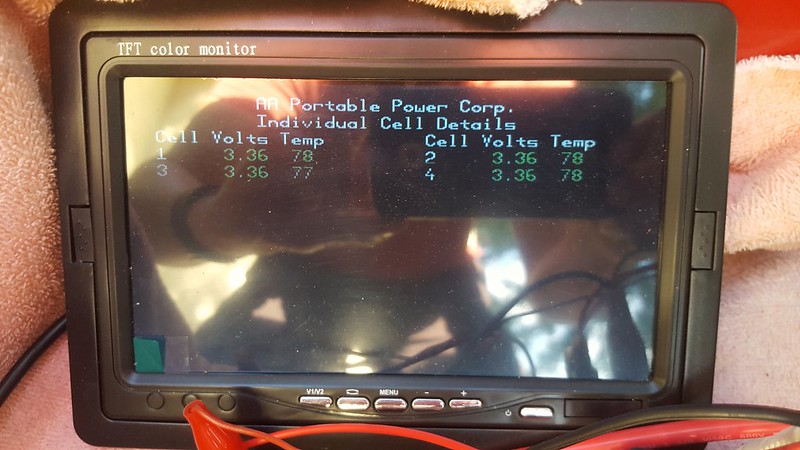

The company I purchased from had balanced the cells but I was keeping a close eye on individual cell voltages while charging. All cells stayed within 0.03 volts of each other. My battery and BMS are made by Elite Power Solutions, also known as GBS batteries.

The nominal specs are : Average 3.2 V (working) 3.65V-3.8V (peak ) 2.5 V ( cut-off low). The batteries spent several hours in the 3.3xV range and was only in the 3.4s for a short period of time and moving from 3.49-3.55 literally happened in a minute or two. As soon as the red light on one balance board came on at 3.55v indicating that cell's resistor was active, the capacity display that had been missing from the LCD monitor came alive. Literally within the 8 seconds or so it took me to throw a blanket over the solar panel it soared from 3.55 to 3.61V. I was shocked, but it didn't spend any more than a few seconds there, but the 3.8v cutoff was probably only a minute or two away at that point. After reaching that first initial full charge I put a load on the battery to bring the SOC down.3.6V will not do any harm to any cell in the battery unless you left it sitting at 3.6V for a long period of time. You have to get to around 4.4V-4.5V before you start doing damage instantly. Your BMS should have disconnected the battery from the power source long before this happens.

That's what the Victron solar charge controller software said, but I'm not sure how that could be. It stated 249 watts, 27.6 v and 16.3 amps, which equals 449 watts. My panel is only a 300w.Are "27.6V & 16.3A" a typo?

The screenshot was taken right as the first balance board light came on at 3.55v and the "real" battery voltage was 14.2v at that point. The charge controller was reading 14.4v but it was not that high.

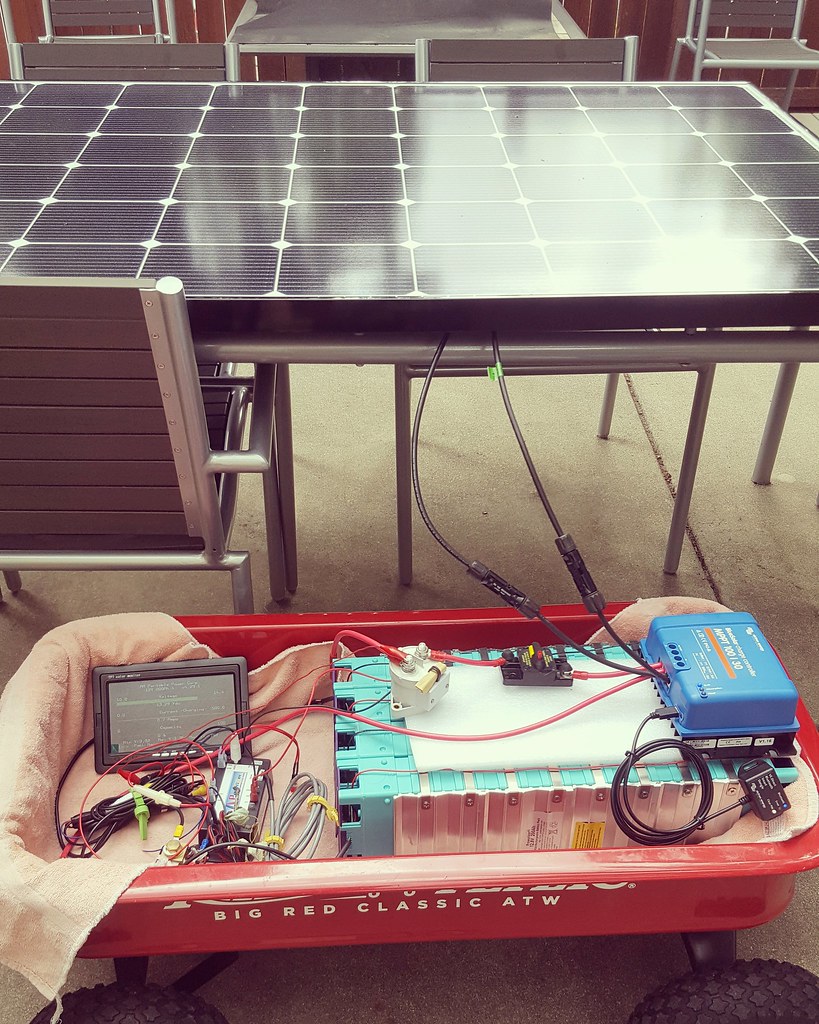

This is just a test rig, so yes, wires are very much undersized compared to the AWG 2 I will be using.You could reduce the both the positive and negative power cable length and/or increase the cable size. From your photo it looks to me like the black battery minus wire from the battery to the shunt is smaller than the other red power wires?

Sounds like a good approach. I'll start low, 13.8v and 10 mins of float and see where I end up.You could set the controller at 14.2V with a long absorb time (say 60 minutes) so that the charge current will taper off and the battery voltage will slowly approach the 14.2V that you want. For normal use at 13.8V an absorb time of around 15 minutes would suffice.

That's what I thought too but the amperage coming from the inverter/charger is only matching the draw from the battery at the time; no charging. There is apparently a cc/cv mode that I have yet to find, so I am interested in researching that.My understanding of float charging is that the power supply will supply whatever current is necessary to keep the battery at the float voltage. I think that if the Magnum supply sees a battery voltage of more than 13V when it is first connected that it will not try to take the battery to the bulk voltage (14.4V?) and skip the absorb phase of the charge. Instead it will provide enough current to charge the battery up to the float voltage of 13.4V. If I am right, if you change the float voltage to 13.8V the Magnum will provide maximum charge current until the battery voltage reaches 13.8V. I did see some settings that imply that you can limit the time that the Magnum will stay in float before shutting down altogether which maybe of use.

Leave a comment:

-

A couple of questionsI was babysitting the batteries for their first full charge today. My BMS needs at least one cell to hit 3.55v (to activate a balance board) for the SOC meter to work. (Only need to do once.) Just as everyone says, one minute the cells were in the mid-to-high 3.4s and within a couple of minutes they were at 3.55 and one hit 3.6 in the next 10 seconds before I could disconnect the solar. I was shocked how quickly that happened, especially since it sat the 3.3s for hours.- Did you balance the cells before the first charge and if so how did you do it?

- What is the make and model of your BMS?

3.6V will not do any harm to any cell in the battery unless you left it sitting at 3.6V for a long period of time. You have to get to around 4.4V-4.5V before you start doing damage instantly. Your BMS should have disconnected the battery from the power source long before this happens.

Are "27.6V & 16.3A" a typo?Under no load my volt meter, the BMS and the solar charge controller all report around the same voltage, but when charging at 27.6V & 16.3A the solar charge controller was reading 0.2 volts higher than the battery voltage. I had to temporarily reprogram the charge controller for 14.4v (even though I wanted a battery voltage of 14.2v) so I could hit my 3.55vpc target. What is the best way to manage this since the charge controller's voltage reading will be higher than the real battery SOC at high charge rates, yet close to reality at lower charge rates?

You could reduce the both the positive and negative power cable length and/or increase the cable size. From your photo it looks to me like the black battery minus wire from the battery to the shunt is smaller than the other red power wires?

You could set the controller at 14.2V with a long absorb time (say 60 minutes) so that the charge current will taper off and the battery voltage will slowly approach the 14.2V that you want. For normal use at 13.8V an absorb time of around 15 minutes would surfice.

My understanding of float charging is that the power supply will supply whatever current is necessary to keep the battery at the float voltage. I think that if the Magnum supply sees a battery voltage of more than 13V when it is first connected that it will not try to take the battery to the bulk voltage (14.4V?) and skip the absorb phase of the charge. Instead it will provide enough current to charge the battery up to the float voltage of 13.4V. If I am right, if you change the float voltage to 13.8V the Magnum will provide maximum charge current until the battery voltage reaches 13.8V. I did see some settings that imply that you can limit the time that the Magnum will stay in float before shutting down altogether which maybe of use.I do have the ME-RC50 remote that allows reprogramming of the bulk, absorb, float voltages but it sounds like that 13.0V is not adjustable. The troubleshooting section of the manual says "Charger says "Float Charging" not "Bulk Charging" when the AC is first plugged in: Check the DC Volts meter, if the battery is over 13.0 VDC then the battery was already charged, and the charger automatically goes to Float Charging to keep from overcharging the batteries."

Simon

Off grid 24V system, 6x190W Solar Panels, 32x90ah Winston LiFeYPO4 batteries installed April 2013

BMS - Homemade Battery logger github.com/simat/BatteryMonitor

Latronics 4kW Inverter, homemade MPPT controller

Leave a comment:

-

It's something I never would have thought about, so thank you. Glad this side orientation works because it's my only choice!Oops, I have got it wrong, upright or on the side is OK, on the back is bad. See here for more information http://visforvoltage.org/forum/9972-...ll-orientation

I was babysitting the batteries for their first full charge today. My BMS needs at least one cell to hit 3.55v (to activate a balance board) for the SOC meter to work. (Only need to do once.) Just as everyone says, one minute the cells were in the mid-to-high 3.4s and within a couple of minutes they were at 3.55 and one hit 3.6 in the next 10 seconds before I could disconnect the solar. I was shocked how quickly that happened, especially since it sat the 3.3s for hours.Yes the rate of charge makes a big difference! Another issue when charging with solar is that the charge current can vary from the maximum the solar panels can put out under full sun to nearly zero during heavy cloud cover or in the early evening which can make a difference to the final %SOC that your battery ends up at.

Under no load my volt meter, the BMS and the solar charge controller all report around the same voltage, but when charging at 27.6V & 16.3A the solar charge controller was reading 0.2 volts higher than the battery voltage. I had to temporarily reprogram the charge controller for 14.4v (even though I wanted a battery voltage of 14.2v) so I could hit my 3.55vpc target. What is the best way to manage this since the charge controller's voltage reading will be higher than the real battery SOC at high charge rates, yet close to reality at lower charge rates?

Right now the battery is sitting at 13.36 v (no load) or 3.345 vac and the BMS is reporting that's about a 92% charge. That seems about right, which might make a good target float voltage. I can see now that 13.2 v would be much lower SOC. Probably too low for my needs.They look fine to me. Having the float voltage at 13.2V (3.3V/cell) will mean that your battery will not be kept at ~95%-98% full while the sun is up. You say you have been looking at the Cruising forum and they say not to keep the battery at a high SOC for extended periods. I agree with this if the battery is not being used or used infrequently, under these circumstances the battery SOC should be kept around 40%-50%. On the other hand if the battery is in use all the time as with my system and other off grid systems with things like fridges switching on and off I don't think this is such an issue. Let me know if you want a technical description of why this is so.

I do have the ME-RC50 remote that allows reprogramming of the bulk, absorb, float voltages but it sounds like that 13.0V is not adjustable. The troubleshooting section of the manual says "Charger says "Float Charging" not "Bulk Charging" when the AC is first plugged in: Check the DC Volts meter, if the battery is over 13.0 VDC then the battery was already charged, and the charger automatically goes to Float Charging to keep from overcharging the batteries."Looking through the MMS1012 manual it looks like the default float voltage is 13.4 (3.35V/cell) which is too low to charge an LFP battery, however if you have the ME-ARC Inverter Remote you can custom program the MMS1012.

I hope there is a way to get around that...

Leave a comment:

-

Oops, I have got it wrong, upright or on the side is OK, on the back is bad. See here for more information http://visforvoltage.org/forum/9972-...ll-orientation

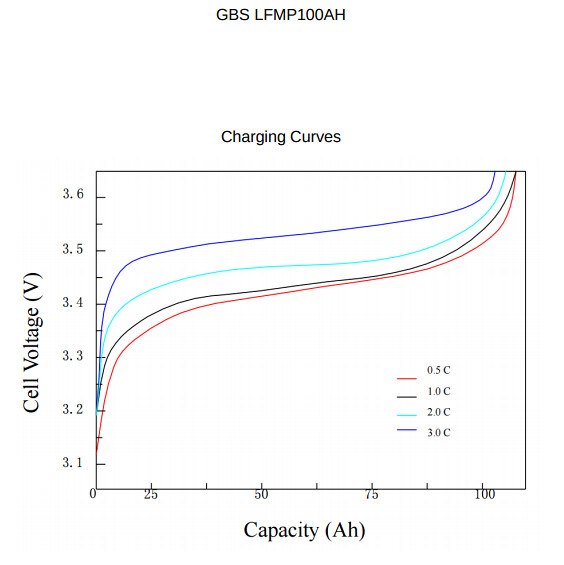

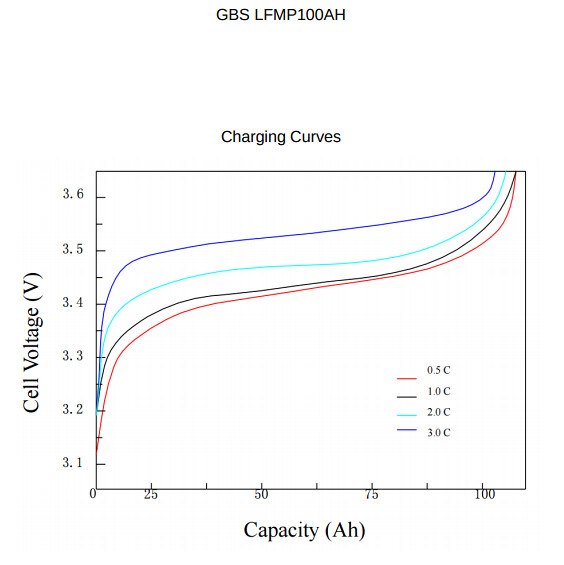

Yes the rate of charge makes a big difference! Another issue when charging with solar is that the charge current can vary from the maximum the solar panels can put out under full sun to nearly zero during heavy cloud cover or in the early evening which can make a difference to the final %SOC that your battery ends up at.Very interesting chart, thank you for posting that. I wonder how similar my GBS cells would be compared to the Winstons. If you look at the chart I posted, 3.35vpc would be about 28% SOC at 0.5C while a .05C charge on your chart could be 65% SOC. Goes to show why you can't rely on voltage with LiFePO4 cells, which makes it a little more nerve wracking for newbies like me.

They look fine to me. Having the float voltage at 13.2V (3.3V/cell) will mean that your battery will not be kept at ~95%-98% full while the sun is up. You say you have been looking at the Cruising forum and they say not to keep the battery at a high SOC for extended periods. I agree with this if the battery is not being used or used infrequently, under these circumstances the battery SOC should be kept around 40%-50%. On the other hand if the battery is in use all the time as with my system and other off grid systems with things like fridges switching on and off I don't think this is such an issue. Let me know if you want a technical description of why this is so.These are the only settings I can adjust in my solar charge controller. Do you see any problems with these settings?

Looking through the MMS1012 manual it looks like the default float voltage is 13.4 (3.35V/cell) which is too low to charge an LFP battery, however if you have the ME-ARC Inverter Remote you can custom program the MMS1012.The charger was only matching the 0.8 amps being pulled by the BMS, contractors & LCD screen, according to the shunt-based reading and I confirmed with a clamp meter.

Simon

Off grid 24V system, 6x190W Solar Panels, 32x90ah Winston LiFeYPO4 batteries installed April 2013

BMS - Homemade Battery logger github.com/simat/BatteryMonitor

Latronics 4kW Inverter, homemade MPPT controller

Leave a comment:

-

That is something I never thought about; particularly since GBS packages these cells, stores and ships them on their side. How critical is this, as it would be very difficult for me to mount this in any position other than on its side.

Very interesting chart, thank you for posting that. I wonder how similar my GBS cells would be compared to the Winstons. If you look at the chart I posted, 3.35vpc would be about 28% SOC at 0.5C while a .05C charge on your chart could be 65% SOC. Goes to show why you can't rely on voltage with LiFePO4 cells, which makes it a little more nerve wracking for newbies like me.Here are some charge/discharge plots I did at the sort of charge rates that we work with.

ChargeDischargeCurves.jpg

These are the only settings I can adjust in my solar charge controller. Do you see any problems with these settings?I charge to 3.45V/cell (13.8V) until the charge current drops to C/50 then drop to a float voltage of 3.35V/cell (13.4V). As you have the balancing circuitry in the BMS you could monitor the imbalance and when it gets too bad raise the charge voltage to 3.55V/cell (14.2V) for a few hours and let your BMS do the balance for you.

Regarding the inverter/charger:

The charger was only matching the 0.8 amps being pulled by the BMS, contractors & LCD screen, according to the shunt-based reading and I confirmed with a clamp meter.Although it is going straight to float it might still put out full current until the battery voltage reaches the float voltage?

Leave a comment:

-

Imbalance in the battery unless it is badly out of balance will only show up when the battery charge voltage is greater than around 3.4V

One thing I noticed with your setup is that you have the batteries on their side. It is bad to leave them on there side as the electrolyte moves to the side of the battery. They should be either preferably upright or on their back.

Here are some charge/discharge plots I did at the sort of charge rates that we work with.I found this chart for the 100 aH GBS cells. Mine are the newer 3rd generation 200aH cells but I assume the curve looks much the same:

The red line, 0.5C, would assume charging at 50amps. I am mostly charging by solar and thus am closer to 0.05C. I am curious how that might look at this graph, as I have no idea what SOC I'm at at. At 3.36vpc (13.44v pack) charging at such a low rate I'm guessing I'm somewhere in the 28% SOC.

ChargeDischargeCurves.jpg

Might be worth looking at solid state MOSFET switches or latching relays, you could also use a normally closed relay to disconnect the solar array from the controller if any cell voltages go too high. Latching relays will be more complex to interface.The BMS, display monitor and 2 contactors are collectively pulling 0.8 amps to stay alive. Not sure I'm happy about that, but even if I were not running a BMS I would still want to implement normally-open safety contactors.

I charge to 3.45V/cell (13.8V) until the charge current drops to C/50 then drop to a float voltage of 3.35V/cell (13.4V). As you have the balancing circuitry in the BMS you could monitor the imbalance and when it gets too bad raise the charge voltage to 3.55V/cell (14.2V) for a few hours and let your BMS do the balance for you.I have the Victron solar charge controller set to BULK=13.8V, ABSORB 1 minute, FLOAT=13.3V. With those settings I will never hit the 3.55vpc required to active the cell balancers, which is precisely what I want--I will monitor for cell drift and manually balance if needed.

Although it is going straight to float it might still put out full current until the battery voltage reaches the float voltage?I am trying to work around an issue with my Magnum inverter/charger. When I plug into shorepower (120VAC) it goes straight to float. Then I read in the manual that "Charger says "Float Charging" not "Bulk Charging" when the AC is first plugged in: Check the DC Volts meter, if the battery is over 13.0 VDC then the battery was already charged, and the charger automatically goes to Float Charging to keep from overcharging the batteries." That doesn't help me if it won't start bulk charging until the battery dips to 12.9V, that is a very low SOC.

Simon

Off grid 24V system, 6x190W Solar Panels, 32x90ah Winston LiFeYPO4 batteries installed April 2013

BMS - Homemade Battery logger github.com/simat/BatteryMonitor

Latronics 4kW Inverter, homemade MPPT controller

Leave a comment:

-

Finally had time to start playing with my 200aH LiFePO4 battery and solar setup. To start, the battery showed up nicely balanced.

It has been raining so I'm dragging the battery in and out of the garage via my daughter's wagon. She isn't thrilled and wants it back.

The spaghetti of wiring is mostly related to the LCD display monitor, so other than a disconnect switch between the solar panel and the charge controller, this is the basic mock-up. Also not shown is a low voltage contactor (operated by the BMS) and the inverter.

I found this chart for the 100 aH GBS cells. Mine are the newer 3rd generation 200aH cells but I assume the curve looks much the same:

The red line, 0.5C, would assume charging at 50amps. I am mostly charging by solar and thus am closer to 0.05C. I am curious how that might look at this graph, as I have no idea what SOC I'm at at. At 3.36vpc (13.44v pack) charging at such a low rate I'm guessing I'm somewhere in the 28% SOC.

The BMS, display monitor and 2 contactors are collectively pulling 0.8 amps to stay alive. Not sure I'm happy about that, but even if I were not running a BMS I would still want to implement normally-open safety contactors.

LETitROLL was absolutely right that Victron has updated the software for the charge controller and it now allows float time adjustable in 1 minute increments, where previously the minimum was 1 hour. I have the Victron solar charge controller set to BULK=13.8V, ABSORB 1 minute, FLOAT=13.3V. With those settings I will never hit the 3.55vpc required to active the cell balancers, which is precisely what I want--I will monitor for cell drift and manually balance if needed.

I am trying to work around an issue with my Magnum inverter/charger. When I plug into shorepower (120VAC) it goes straight to float. Then I read in the manual that "Charger says "Float Charging" not "Bulk Charging" when the AC is first plugged in: Check the DC Volts meter, if the battery is over 13.0 VDC then the battery was already charged, and the charger automatically goes to Float Charging to keep from overcharging the batteries." That doesn't help me if it won't start bulk charging until the battery dips to 12.9V, that is a very low SOC.Leave a comment:

-

Do you know how to Bottom Balance and operate? Regardless if you go Top Middle or Bottom it all takes the same equipment to set up for the Initial Balance aka Bulk Balance.

All start the same way. When you get them, wire all of them in parallel and walk away for a day. You will need something like a Revolectric PL8 or similar. To BB you would discharge to 2.5 volts, or for TB charge to 3.6 volts. You can BB using large wattage power resistors. Example for 4S say 100 watt, 0.1 Ohms, and a 10 watt 1 Ohm resistor. But to do that you cannot take your eyes off the voltmeter, at least not at the end. Once you hit about 3 volts, things happen real fast, and if you were to let the voltage go below 2-volts can be a very expensive mistake.

Once you get it down to 2.5 volts. You switch to the 10 watt 1 ohm resistor. To slow things down a lot. You keep bleeding until you get a voltage no higher than 2.5 volts and no lover than 2.4 volts rested. By rested I mean several hours open circuit voltage.

With a PL8 of like charger is simple and hands free. Completely automated and foolproof. Not to mention the best charger you can buy. Will charge any battery type of today and in the future. You can even use the PL8 as your battery monitor.

EDIT NOTE:

If you are going to Bottom Balance, do not be firm on an absolute hard charge voltage number of say 13.8. You will need to run a few cycles to find the right voltage. What you are looking for is the one cell with the highest voltage. You stop charging when that ONE CELL reaches 3.5 volts. If you are lucky all of them will be 3.5 volts, and if that is the case, your new target is 13.8 volts which will be 3.45 volts on every cell. Here is the catch That would mean you are the luckiest man alive because every cell is perfectly matched with the same capacity. What you are looking for is a voltage, it will be between 13.6 to 13.8 volts where 3 of the 4 cells are roughly 3.45 volts and that one week cell is 3.46 to 3.5 volts. That final voltage will be equal to or less than 13.8 volts. Just do not let any of them go above 3.5 volts.

If you could do that then you can do what commercial EV's do, Middle Balance. You charge to 90% and disconnect at 10%. Set your Inverter LVD for 12 volts. Over discharge is the worse thing you can do letting any cell go below 2.5 volts. With your Inverter LVD set to 12 volts and Bottom Balance eliminates that risk. Be sure to check cell balance as part of your normal PM routine.

I have other ways to Bottom Balance if none of the above are doable for you. So please ask questions until you are confident you know WTF you are doing and why.Last edited by Sunking; 04-27-2017, 08:55 PM.Leave a comment:

-

^^ Good stuff Sunking, thank you. I ordered my GBS batteries yesterday and will pick them up in person in 2 weeks. Then off to bottom balance camp for me.Leave a comment:

-

Well I build some EV's and no one I know with an EV uses 4S. Certainly no one with an EV would charge to 3.2 vpc as that is nominal and less than 50% SOC

My concern is this, the resting voltage of these cells is around 3.3V (13.2V in 4S) . I'm reading that holding (floating) the cells at 13.8V will cause the premature degradation I am trying to avoid, hence the 13.2V float setting that has been recommended by some on various EV and sailboat forums.

Secondly you will not be Floating in the logical sense. Floating means you apply a FLOAT voltage and hold it there for eternity aka Float Service. Lastly someone on those Sailboat Forums needs to get back on land and tell A123 Systems they should not reccomend Floating LiFeP04 cells at 3.45 volts. I am sure A123 will appreciate some drunk sailor how to run their biz and set battery specifications.

Take a look at the Spec Sheet note FLOAT VOLTAGE = 3.45 volts. What more so you want? A manufacture spec, or a drunken sailor?

Like I have said the allowable range for Float is 3.4 to 3.45 volts. On a 4S pack is 13.6 to 13.8 volts. My guess is your Controller only has a resolution of 0.1 volts. That gives you 3 choices of 13.6, 13.7, and 13.8. Take your pick and quit making it more complicated than it really is.

One last comment. Genasun is the premier Marine MPPT Charge Controllers for LFP batteries. If you were to buy a model GV 10-L 14.2 made for LFP batteries comes in one flavor of 14.2 volts until the sunsets.Last edited by Sunking; 04-27-2017, 08:37 PM.Leave a comment:

-

My concern is this, the resting voltage of these cells is around 3.3V (13.2V in 4S) . I'm reading that holding (floating) the cells at 13.8V will cause the premature degradation I am trying to avoid, hence the 13.2V float setting that has been recommended by some on various EV and sailboat forums. There's a 382 page thread (seriously) on the sailing forums around LiFePO4 charging characteristics, so I'm just collecting data at this point. Clearly I'm here because I appreciate the education and an alternative viewpoint.No somewhere between 80 and 90%. The actual voltage you will have to experiment a bit with to find the sweat spot. Final voltage will be in the range of 13.6 to 13.8 volts. If your charger resolution is only 0.1 volts gives you 3 choices.

Not sure where that was recommended. But the difference is this. If you charge to say 13.8, than fall back to 13.2 volts, you are now on battery power, not solar power. Leave it at 13.8 which is short of fully charged, the batteries will Saturate (stop charging) and assuming you still have daylight, power comes from the panels saving your batteries for after dark.

Leave a comment:

-

No somewhere between 80 and 90%. The actual voltage you will have to experiment a bit with to find the sweat spot. Final voltage will be in the range of 13.6 to 13.8 volts. If your charger resolution is only 0.1 volts gives you 3 choices.

Not sure where that was recommended. But the difference is this. If you charge to say 13.8, than fall back to 13.2 volts, you are now on battery power, not solar power. Leave it at 13.8 which is short of fully charged, the batteries will Saturate (stop charging) and assuming you still have daylight, power comes from the panels saving your batteries for after dark.

You are trying to compare lead acid techniques to Lithium. In a Pb battery you want and must charge to 100% and that requires the batteries to Saturate at 14.4 volts, and then set back to 13.8 volts for Float and then the panels supply power. You do not do that with LFP batteries. If you charge to 100% (14.4 volts than cut back, th ebatteries have to discharge before the panels can supply power.

You do not want to charge LFP batteries to 100% like lead acid. they work exactly opposite. With Lead Acid if you do not recharge to 100% immediately after every use, you cut cycle life in half. A solar system is not capable of charging Lead Acid batteries to 100% all the time. If you charge LFP to 100%, you cut cycle life in half. LFP works best in a partial state of charge (PSOC). Lead Acid batteries work best at 100% SOC.

No commercial EV manufactures allow users to fully charge the battery. Most operate 80/20, and some 90/10. That is the only way they can offer long warranties. Otherwise they would go bankrupt with warranty claims. You have to get out of that lead acid box thinking or your adventure in Lithium will be short, expensive, and painful.

As I just told another user, there are 4 voltages you need to focus on. 3 and 3.45 volts which are cell voltages. Also need to focus on 12 and 13.8 volts which is pack voltage. Never let a cell go below 3 volts or pack voltage go below 12 volts under discharge, and never allow a cell to go above 3.45 volts or 13.8 volts while charging. First thing to do is set the charger to 13.8 volt, and the LVD on your inverter to 12 volts. If you want a second added layer of protection requires a Smart Cell Monitor to signal the LVD if anyone cell goes below 3 volts while discharging, or signal the Charger to shut off any anyone cell goes above 3.45 volts.

Leave a comment:

-

3.65vpc is full on a GBS cell. Charging to 3.45vpc (13.8V for a 4S) would be about 94%, no? I asked this earlier but probably didn't understand the answer--what's the difference between setting bulk, absorb and float to 13.8V versus setting Bulk to 13.8V and float at 13.2V as recommended earlier in the thread?Leave a comment:

-

Not done that way. You set Bulk = Absorb = Float. That makes your charger into a plain ole CC/CV Float charger. You just charge up to 90% and Float. There no stages.

Leave a comment:

Copyright © 2014 SolarReviews All rights reserved.

Powered by vBulletin® Version 6.1.3

Copyright © 2025 MH Sub I, LLC dba vBulletin. All rights reserved.

Copyright © 2025 MH Sub I, LLC dba vBulletin. All rights reserved.

All times are GMT-5. This page was generated at 09:21 AM.

Leave a comment: