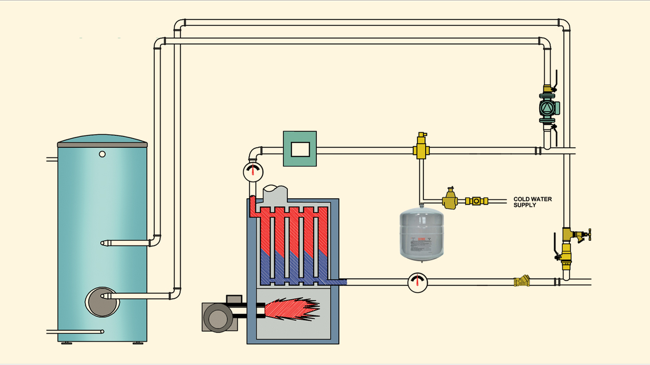

I am thinking of getting a free 500 g propane tank, spraying the outside with sticky foam, adding a 30 psi T/P valve then building a shed around it. I am thinking of plumbing the same water from registers into the tank, and leaving it pressurized. Any concerns with oils, rust or something else I haven't considered?

Try our solar cost and savings calculator

Old Propane Tank for Storage

Collapse

This topic is closed.

X

X

-

-

If you're in the U.S, since the tank is most likely an A.S.M.E. pressure vessel, BEFORE you spray the tank, I'd have the tank thoroughly cleaned and inspected and then pressure tested, all by some outfit that pressure tests tanks and other pressure vessels to A.S.M.E. Section 8 standards for testing of unfired pressure vessels.

In building the structure around it, don't build the boat in the basement. So, don't forget to design the structure it so that either the tank can be removed from the structure or the structure can be dismantled to move the tank.

Make the foam thickness at least 2", more is better and spry the tank supports as well.

-

Propane tanks have an oily odorant inside ( so you can smell a propane leak) be sure that's all cleaned out before you put it into servicePowerfab top of pole PV mount (2) | Listeroid 6/1 w/st5 gen head | XW6048 inverter/chgr | Iota 48V/15A charger | Morningstar 60A MPPT | 48V, 800A NiFe Battery (in series)| 15, Evergreen 205w "12V" PV array on pole | Midnight ePanel | Grundfos 10 SO5-9 with 3 wire Franklin Electric motor (1/2hp 240V 1ph ) on a timer for 3 hr noontime run - Runs off PV ||

|| Midnight Classic 200 | 10, Evergreen 200w in a 160VOC array ||

|| VEC1093 12V Charger | Maha C401 aa/aaa Charger | SureSine | Sunsaver MPPT 15A

solar: http://tinyurl.com/LMR-Solar

gen: http://tinyurl.com/LMR-ListerComment

-

IMO even if you have removed all of the oily or foreign substances from the tank I would install some type of charcoal filter that will capture anything else that resides in the tank and is now in your water.Comment

-

You may to have to weld another tap to the tank to be able to use it. DANGER !!!! DO NOT weld to the tank unless its filled with water. I recommend you get someone that's experienced in welding to flammable containers.Comment

-

If the OP is in a jurisdiction that regulates how pressure vessels are used, that jurisdiction will most likely follow ASME Sec. VIII rules for repairs, modification and subsequent required testing and certification. For another thing, there may be size limitations on how big a pressure vessel can be put on a residential site. In any case, the welding/repair/mods. can probably be on site (by qualified personnel) but most likely the tank will need to be empty when modified if code welding procedures are followed, if for no other reason than inspection requirements, at least until hydrostatic pressure test - if, depending on tank size, material and other requirements, a hydrotest is required.

I appreciate a lot goes on that the AHJ doesn't see, but safety and codes take on an added importance when pressurized tanks are involved. It's the reason the entire ASME Pressure Vessel Code came into existence and, like it or not, it's still a huge bureaucracy that most jurisdictions and a good part of the industrialized world follows.

I spent a lot of time designing pressure vessels for a living with a fair portion of that time writing procedures to conform to ASME sec. IX (welding and metal joining). I never wrote or signed off on a Weld Procedure or Procedure Qualification Record that involved a liquid present in the tank during fabrication, at least until hydrotest. Among other things, welding on a filled or partially filled tank could present real safety problems or at least damage or compromise the integrity and strength of the weld in progress.

I'd urge the OP to get ahold of the AHJ and investigate what needs to be done before proceeding further, and then find someone licensed and qualified to do what's needed in a safe and legal manner.

Better safe than sorry or taking semi anonymously given knowledge like all this from the net.Comment

-

I appreciate the concern, but I am not too concerned. I have welded and cut old propane tanks many times and yes, one should be careful, but it is do-able with precautions. Actually there are a multitude of fittings on most tanks that I know of, so I only need one inlet, one outlet, and maybe a port for a thermistor, so I don't plan on doing any cutting.

These tanks are thick steel, so yes as I posted above, they rust, but I have had one full of water for years with little damage. Iron pipe rusts too, and is about the same thickness or thinner. If it rusts through eventually, no biggie.

Cleaning the tank will not be too hard if I use a pressure washer with a sewer head on it. Lots of Dawn and rinsing should work well enough, but I am sure there will still be some oil that gets into the system. I don't see this as a problem even for things like T/P valves at such low concentration.

I only plan to put 30 psi in it max, and would prefer to put even less pressure in the system. Even if the T/P valve fails, would 30 psi be much of a pop? Full of water there isn't much explosive expansion. These tanks are built for 100-200. It will be in a shed and outdoors too.

I forgot to say that I will probably need a second (and perhaps quite large) hydronic expansion tank. I plan to keep the tank pretty full to minimize expansion.

I think this will work fine. I have ticked off a mod -erator in another thread so all my posts might disappear, so if they do you may wish to copy what is written here.

I promise to let you know if I am successful, or not. No, I do not expect to blow myself up.Comment

-

Powerfab top of pole PV mount (2) | Listeroid 6/1 w/st5 gen head | XW6048 inverter/chgr | Iota 48V/15A charger | Morningstar 60A MPPT | 48V, 800A NiFe Battery (in series)| 15, Evergreen 205w "12V" PV array on pole | Midnight ePanel | Grundfos 10 SO5-9 with 3 wire Franklin Electric motor (1/2hp 240V 1ph ) on a timer for 3 hr noontime run - Runs off PV ||

|| Midnight Classic 200 | 10, Evergreen 200w in a 160VOC array ||

|| VEC1093 12V Charger | Maha C401 aa/aaa Charger | SureSine | Sunsaver MPPT 15A

solar: http://tinyurl.com/LMR-Solar

gen: http://tinyurl.com/LMR-ListerComment

-

You certainly may do as you want but the methods and procedures you describing and writing about above can be dangerous and in many jurisdictions illegal.I appreciate the concern, but I am not too concerned. I have welded and cut old propane tanks many times and yes, one should be careful, but it is do-able with precautions. Actually there are a multitude of fittings on most tanks that I know of, so I only need one inlet, one outlet, and maybe a port for a thermistor, so I don't plan on doing any cutting.

These tanks are thick steel, so yes as I posted above, they rust, but I have had one full of water for years with little damage. Iron pipe rusts too, and is about the same thickness or thinner. If it rusts through eventually, no biggie.

Cleaning the tank will not be too hard if I use a pressure washer with a sewer head on it. Lots of Dawn and rinsing should work well enough, but I am sure there will still be some oil that gets into the system. I don't see this as a problem even for things like T/P valves at such low concentration.

I only plan to put 30 psi in it max, and would prefer to put even less pressure in the system. Even if the T/P valve fails, would 30 psi be much of a pop? Full of water there isn't much explosive expansion. These tanks are built for 100-200. It will be in a shed and outdoors too.

I forgot to say that I will probably need a second (and perhaps quite large) hydronic expansion tank. I plan to keep the tank pretty full to minimize expansion.

I think this will work fine. I have ticked off a mod -erator in another thread so all my posts might disappear, so if they do you may wish to copy what is written here.

I promise to let you know if I am successful, or not. No, I do not expect to blow myself up.

At the minimum, what and how you write of it runs contrary to common and good accepted practice and reads to me to be written by someone who is ignorant of pressure vessel technology and the precautions necessary for safe fabrication and operation of pressure vessels.

I'd caution other readers of your posts that discuss such things to be very cautious of taking what you write seriously.

As a retired P.E. (mechanical) who, until retired, claimed professional proficiency in pressure vessel design, fabrication and testing, and did stints on ASME Pressure vessel subcommittees that interpreted sections of the A.S.M.E. Boiler and Pressure Vessel Code, I'd respectfully suggest the moderators of this forum consider remedial action to remove this post and others from you that spread what could easily be interpreted as dangerous information.

Nothing personal, but IMO only based in your above exhibited ignorance - which looks to me to border on the profound - and also what looks to be to be your unconcern for the safety of others, you're spreading unsafe and dangerous information.Comment

-

There is a fundamental flaw in the understanding of an expansion tank here, and the thread is now locked with this warning about a dangerous design flawPowerfab top of pole PV mount (2) | Listeroid 6/1 w/st5 gen head | XW6048 inverter/chgr | Iota 48V/15A charger | Morningstar 60A MPPT | 48V, 800A NiFe Battery (in series)| 15, Evergreen 205w "12V" PV array on pole | Midnight ePanel | Grundfos 10 SO5-9 with 3 wire Franklin Electric motor (1/2hp 240V 1ph ) on a timer for 3 hr noontime run - Runs off PV ||

|| Midnight Classic 200 | 10, Evergreen 200w in a 160VOC array ||

|| VEC1093 12V Charger | Maha C401 aa/aaa Charger | SureSine | Sunsaver MPPT 15A

solar: http://tinyurl.com/LMR-Solar

gen: http://tinyurl.com/LMR-ListerComment

Copyright © 2014 SolarReviews All rights reserved.

Powered by vBulletin® Version 6.1.3

Copyright © 2026 MH Sub I, LLC dba vBulletin. All rights reserved.

Copyright © 2026 MH Sub I, LLC dba vBulletin. All rights reserved.

All times are GMT-5. This page was generated at 12:08 PM.

Comment