I've been reading the code book online and also have the help of a certified electrician (the guy who is doing all my meter base/main upgrades since the tree incident).

The AHJ gave me the specific codes that I'd need to meet and links to online sources to read up on it. He's a pretty good guy.

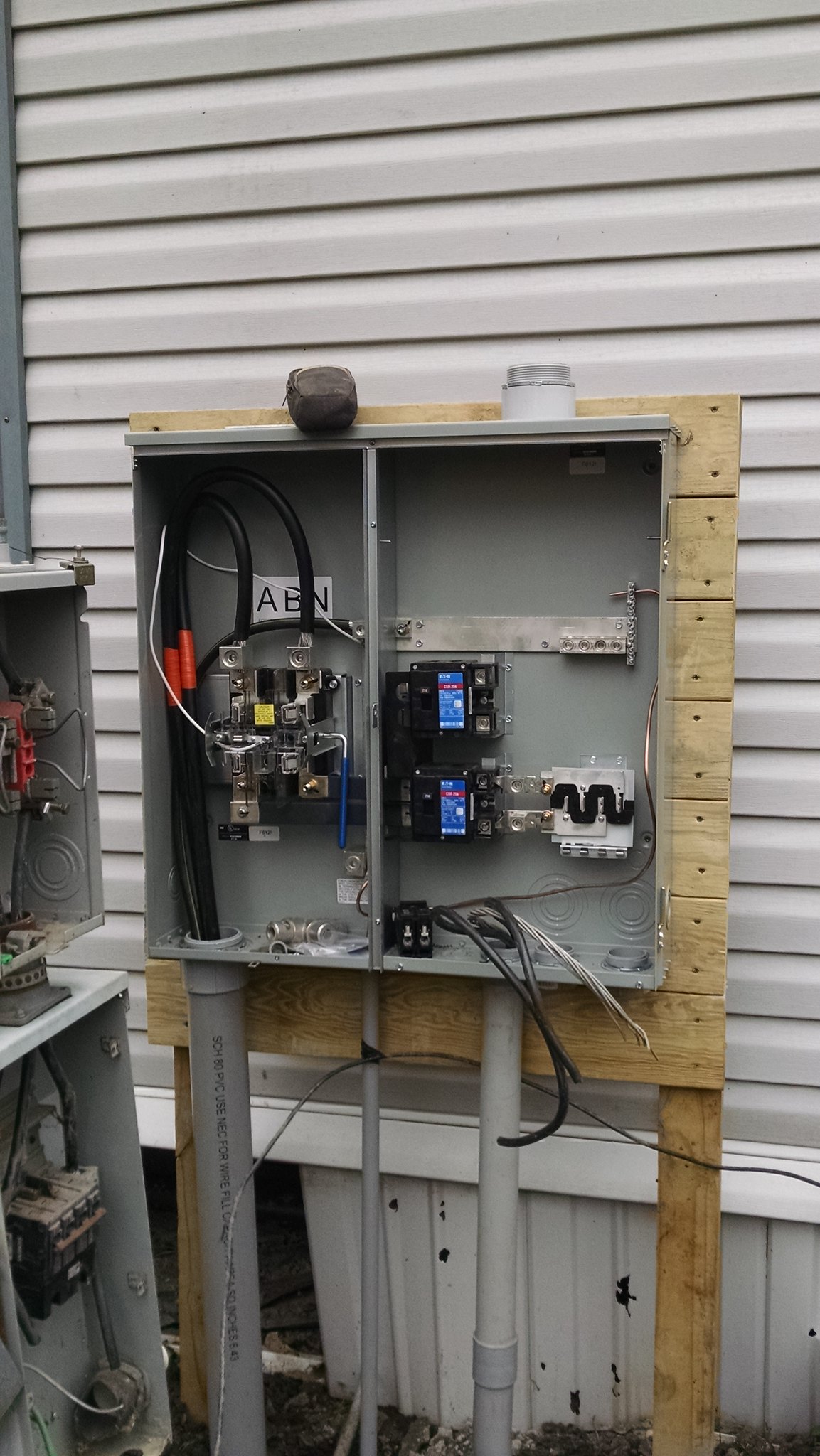

Hopefully, my equipment will be shipping out next week. Our new 400a service is being started on today. They are currently setting up the meter base.

The AHJ gave me the specific codes that I'd need to meet and links to online sources to read up on it. He's a pretty good guy.

Hopefully, my equipment will be shipping out next week. Our new 400a service is being started on today. They are currently setting up the meter base.

Comment