What is the best method to get the ground wire into the building?

I'm planning on doing a microinverter (enphase M250) setup.

GEC isn't needed, but an EGC is required for the racking and modules.

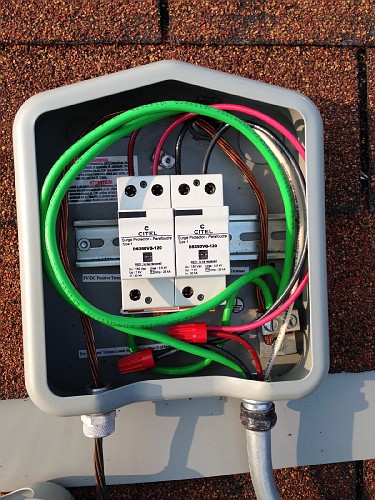

Option 1 is to drill a hole big enough for #10 wire in bottom of the j-box and connect to the ground inside there. (con: makes it no longer waterproof)

Option 2 is to run #10 across the roof, around the gutter and down the outside of the wall. (con: ugly IMO)

There's got to be a better way to do it.

I'm tentatively planning on using #10, since the extra #4 copper I have laying around is too big for the WEEB lugs. (Unless someone can point me to ones that take #4 copper)

I'm planning on doing a microinverter (enphase M250) setup.

GEC isn't needed, but an EGC is required for the racking and modules.

Option 1 is to drill a hole big enough for #10 wire in bottom of the j-box and connect to the ground inside there. (con: makes it no longer waterproof)

Option 2 is to run #10 across the roof, around the gutter and down the outside of the wall. (con: ugly IMO)

There's got to be a better way to do it.

I'm tentatively planning on using #10, since the extra #4 copper I have laying around is too big for the WEEB lugs. (Unless someone can point me to ones that take #4 copper)

Comment