Hello everyone,

Is there a standard/recommendation regarding the acceptable degree of shading of a solar panel?

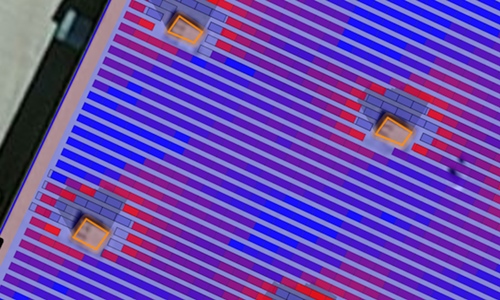

I am using PVSol to simulate shading from surrounding structures. The results of ‘Shade Frequency Distribution’, expressed in % for each module, is the annual average of irradiation reduction. This number goes from 0% (absolutely no shade) to100% fully shaded. I think I have read that this number should be less than 1%, but I can’t seem to remember the source of this info. Is it true? How much shading is acceptable, in %?

Thanks

Is there a standard/recommendation regarding the acceptable degree of shading of a solar panel?

I am using PVSol to simulate shading from surrounding structures. The results of ‘Shade Frequency Distribution’, expressed in % for each module, is the annual average of irradiation reduction. This number goes from 0% (absolutely no shade) to100% fully shaded. I think I have read that this number should be less than 1%, but I can’t seem to remember the source of this info. Is it true? How much shading is acceptable, in %?

Thanks

Comment