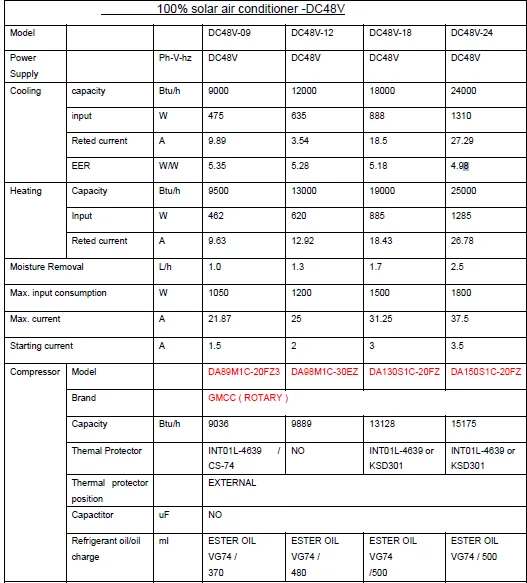

Just wondering if anyone has "taken the plunge" for one of those $1,800 48vDC mini-split air conditioners that can be found at various places online? (I'm aware that they are not exactly cheap, and that A/C is by no means the most feasible thing to run on a solar system. I have been through an HVAC class, and am very electrically literate; hookup/install is no problem at all.)

To be clear, I'm referring to the pure DC units, NOT a "split" system that requires AC, or one that requires solar panels to be directly connected to it.

If so, what unit did you buy, and why?

How is it holding up?

Does it cool/heat as expected?

What is the general measured power consumption?

Has it been worth the cost?

To be clear, I'm referring to the pure DC units, NOT a "split" system that requires AC, or one that requires solar panels to be directly connected to it.

If so, what unit did you buy, and why?

How is it holding up?

Does it cool/heat as expected?

What is the general measured power consumption?

Has it been worth the cost?

Comment