Hi all,

RyanH has made great progress creating ultralight solar PV USB charging devices for lightweight backpacking, greatly beating the power-to-weight ratio of commercially available systems (like the Bushnell PowerSync SolarWrap Mini using Powerfilm cells).

Anyone have any suggestions on improvements? (Please post here, not at forum links below)

A high level summary of components (if you prefer not to follow the links below):

He detailed a newer device (1.7oz, 9.4W max theoretical, about 6W in real usage) here: Facebook group post

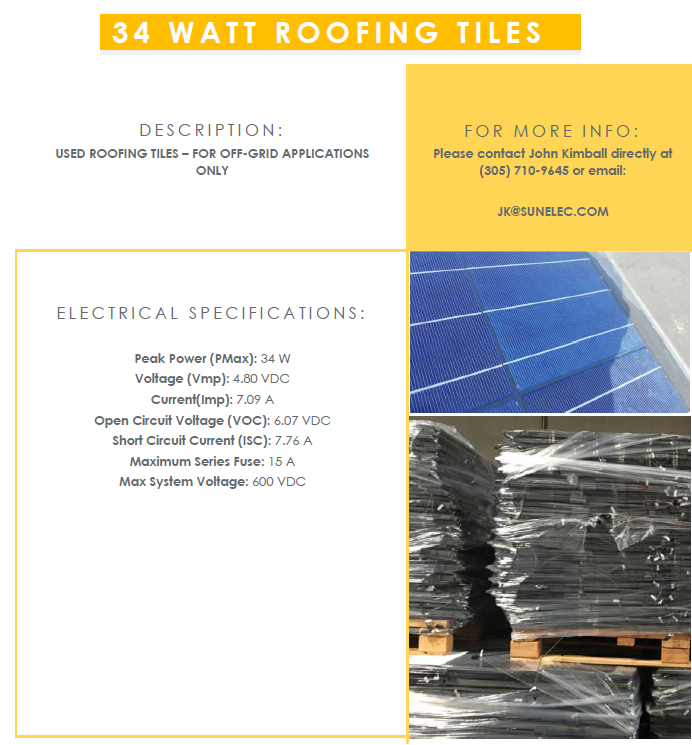

ULSolarPVUSBCharger2.jpg

Some thoughts:

1. DC-DC USB converter: If we could find a converter like the Adafruit VERTER 5V USB Buck-Boost converter that could boost lower voltage and operate in a V and A range produced by the cells, the device might also produce power in lower power conditions. (The design avoids a battery to reduce weight since the devices being charged already have their own batteries.)

2. Series wiring of half and quarter cells: The cells are half or quarter cells wired in series to get the V and A into a range supported by the DC-DC converter. Of course, this means any shade cuts off power production, but the high power-to-weight ratio and strong solid copper backing of the SunPower Maxeon cells makes this trade-off worthwhile currently.

3. Carbon fiber vs Depron foam: RyahH reports the foam might not be durable enough after a long hike with a device on his pack. Carbon fiber panels or a combo of carbon fiber and Depron foam (which is disappearing from market due to manufacturer) might be worth the heavier weight trade-off. (Many of the structural ideas are from the lightweight RC airplane community.)

4. RyanH has tried many different lightweight encapsulants/protective coverings for the panels - Freeze-Tite and Krylon Clear Gloss spray paint for example - but reports some scratching on his panels during his last long hike with the panels hanging off his pack. Someone else reported success with Flex Seal Clear. I don't know the light transmission, haze, or chemical interactivity stats of any of these.

Thanks!

-Jason

P.S. I emailed RyanH a link to this post - he's provided lots of great info to me via email. The photo is also from RyanH.

P.P.S. This is DIY/MYOG (Make Your Own Gear) - it used to have more links to actual and possible components used in making the panel but admins considered them advertisement links and removed them.

RyanH has made great progress creating ultralight solar PV USB charging devices for lightweight backpacking, greatly beating the power-to-weight ratio of commercially available systems (like the Bushnell PowerSync SolarWrap Mini using Powerfilm cells).

Anyone have any suggestions on improvements? (Please post here, not at forum links below)

A high level summary of components (if you prefer not to follow the links below):

- SunPower Maxeon cells due to their light weight and solid copper backing, increasing their strength and decreasing need for additional stronger backing. Cells are half or quarter cut to get to V and A needed for DC-DC converter

- Depron foam backing due to combination of light weight and stiffness (but may not be durable enough)

- A specific DC-DC buck down converter due to light weight, efficiency, and Apple charging support

- A lightweight covering/"encapsulant" (spray-on) to reduce weight vs plastic films or glass

He detailed a newer device (1.7oz, 9.4W max theoretical, about 6W in real usage) here: Facebook group post

ULSolarPVUSBCharger2.jpg

Some thoughts:

1. DC-DC USB converter: If we could find a converter like the Adafruit VERTER 5V USB Buck-Boost converter that could boost lower voltage and operate in a V and A range produced by the cells, the device might also produce power in lower power conditions. (The design avoids a battery to reduce weight since the devices being charged already have their own batteries.)

2. Series wiring of half and quarter cells: The cells are half or quarter cells wired in series to get the V and A into a range supported by the DC-DC converter. Of course, this means any shade cuts off power production, but the high power-to-weight ratio and strong solid copper backing of the SunPower Maxeon cells makes this trade-off worthwhile currently.

3. Carbon fiber vs Depron foam: RyahH reports the foam might not be durable enough after a long hike with a device on his pack. Carbon fiber panels or a combo of carbon fiber and Depron foam (which is disappearing from market due to manufacturer) might be worth the heavier weight trade-off. (Many of the structural ideas are from the lightweight RC airplane community.)

4. RyanH has tried many different lightweight encapsulants/protective coverings for the panels - Freeze-Tite and Krylon Clear Gloss spray paint for example - but reports some scratching on his panels during his last long hike with the panels hanging off his pack. Someone else reported success with Flex Seal Clear. I don't know the light transmission, haze, or chemical interactivity stats of any of these.

Thanks!

-Jason

P.S. I emailed RyanH a link to this post - he's provided lots of great info to me via email. The photo is also from RyanH.

P.P.S. This is DIY/MYOG (Make Your Own Gear) - it used to have more links to actual and possible components used in making the panel but admins considered them advertisement links and removed them.

Comment