Try our solar cost and savings calculator

new NiFe battery bank avaib, orignal buyer ???

Collapse

X

-

-

Is that just a regular 3/4" copper pipe you are using? What are you tinning it with, just regular lead? Great Photos!Comment

-

I forgot what size pipe it was, 3/4 or 1", I had to go up 1 size from my prototype, to not punch the hole through 95% of the meat, it was the thicker, underground rated rigid copper in 10 foot sticks, not coiled thinwall tubing. It was about 50/50 tin lead, used a couple rolls of electrical solder and a block of plumbers lead, lots of wire brush inside and out, and lots of flux. Then a good wash to get the acid based flux out, and flattened and tinned again, Still look like new now,

If it's worth doing, it's worth overdoing !Powerfab top of pole PV mount (2) | Listeroid 6/1 w/st5 gen head | XW6048 inverter/chgr | Iota 48V/15A charger | Morningstar 60A MPPT | 48V, 800A NiFe Battery (in series)| 15, Evergreen 205w "12V" PV array on pole | Midnight ePanel | Grundfos 10 SO5-9 with 3 wire Franklin Electric motor (1/2hp 240V 1ph ) on a timer for 3 hr noontime run - Runs off PV ||

|| Midnight Classic 200 | 10, Evergreen 200w in a 160VOC array ||

|| VEC1093 12V Charger | Maha C401 aa/aaa Charger | SureSine | Sunsaver MPPT 15A

solar: http://tinyurl.com/LMR-Solar

gen: http://tinyurl.com/LMR-ListerComment

-

Good job. I made my own battery lugs out of copper pipe, I never thought of tinning them. I guess that is a good way to stave off corrosion. Lugs are damn expensive.Comment

-

I remember reading somewhere that back in the day in L/A cells the "forming charge" was really critical.

I am wondering if a similar situation exists with Nickel cells?

Have you ever run your bank down and measured the capacity?

Comment

-

from what I recall,, it's slow with NiFe if you can't hith them hard, but it does not damage them. And I'm living on them, not able to flatten them to measure capacity, But last year when I increased absorb time, I saw a big increase in voltage hold overnight, and much better this winterPowerfab top of pole PV mount (2) | Listeroid 6/1 w/st5 gen head | XW6048 inverter/chgr | Iota 48V/15A charger | Morningstar 60A MPPT | 48V, 800A NiFe Battery (in series)| 15, Evergreen 205w "12V" PV array on pole | Midnight ePanel | Grundfos 10 SO5-9 with 3 wire Franklin Electric motor (1/2hp 240V 1ph ) on a timer for 3 hr noontime run - Runs off PV ||

|| Midnight Classic 200 | 10, Evergreen 200w in a 160VOC array ||

|| VEC1093 12V Charger | Maha C401 aa/aaa Charger | SureSine | Sunsaver MPPT 15A

solar: http://tinyurl.com/LMR-Solar

gen: http://tinyurl.com/LMR-ListerComment

-

Not the same chemistry, but in early development of cylindrical NiCd batteries the military did an overcharge test on some 2 AH D cells. After months of 1C charging (with cooling) they tested them and found they now had 10AH cells.SunnyBoy 3000 US, 18 BP Solar 175B panels.Comment

-

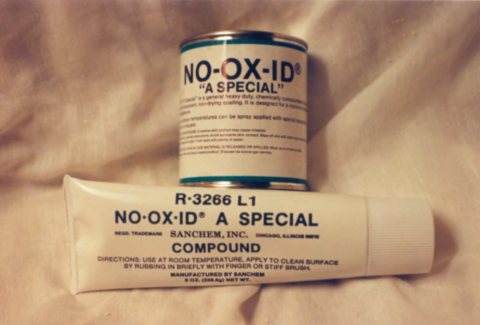

Corrosion should never be an issue if treated and terminated properly. You need to discover NO-OX-ID A Special and learn how to use it. There are 40 year old battery plants out there with absolutely no corrosion issues.

MSEE, PEComment

-

Comment

-

no, I don't have that info. On good news, my bank still is going strong, but it's still drinking distilled water like a camel.Powerfab top of pole PV mount (2) | Listeroid 6/1 w/st5 gen head | XW6048 inverter/chgr | Iota 48V/15A charger | Morningstar 60A MPPT | 48V, 800A NiFe Battery (in series)| 15, Evergreen 205w "12V" PV array on pole | Midnight ePanel | Grundfos 10 SO5-9 with 3 wire Franklin Electric motor (1/2hp 240V 1ph ) on a timer for 3 hr noontime run - Runs off PV ||

|| Midnight Classic 200 | 10, Evergreen 200w in a 160VOC array ||

|| VEC1093 12V Charger | Maha C401 aa/aaa Charger | SureSine | Sunsaver MPPT 15A

solar: http://tinyurl.com/LMR-Solar

gen: http://tinyurl.com/LMR-ListerComment

-

Comment

Copyright © 2014 SolarReviews All rights reserved.

Powered by vBulletin® Version 6.1.3

Copyright © 2026 MH Sub I, LLC dba vBulletin. All rights reserved.

Copyright © 2026 MH Sub I, LLC dba vBulletin. All rights reserved.

All times are GMT-5. This page was generated at 03:03 PM.

Comment