Sylgard

I'm in the middle of my first panel build and I'm trying to do a professional-looking or better job building a 280 Watt 72-cell panel using 6x6 cells. I've assembled and painted the aluminum frame and ordered the tempered glass.

My current plan is to use Sylgard-184 to encapsulate. Has anyone had luck getting the air bubbles out? Has anyone tried Sylgard-182 which has a longer cure time than the 184? Perhaps that would help?

I'm thinking about using an eye-dropper to help remove air. Not sure if that will work or not.

Here's a url to a DOW manual with a couple of tips:

Try our solar cost and savings calculator

Epoxy for encapsulating cells (great DIY thread with photos!)

Collapse

This topic is closed.

X

This is a sticky topic.

X

X

-

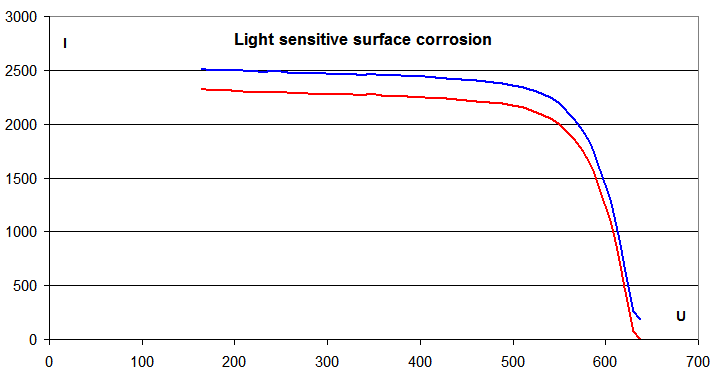

See for non-encapsulated solar cells degrade here:It would be very interesting to compare the performance of the panels with encapsulated cell with the non-encapsulated cells.

It seems to me that the absence of encapsulation or ineffective encapsulation is the one of the major problems with DIY solar panels. Is there any info on how quickly non-encapsulated cells degrade due to water vapour?

Can we have lots of BIG piccies of encapsulated solar cells please?

thanks

Phil

Bare solar cells exposed to the elements

www.avdweb.nlLeave a comment:

-

the only alternatives seem to be using normal silicone to hold the cells in place and hope for the best, this still appears to be only a bit less than half the price of sylgard etc, i did try it, and the results are not that great, the cells are not encapsulated at all really and time will tell the results. would love to see the epoxy results but not a single image has been shown so far, the repairability factor would concern me in the case of a mistake or broken cell. can totally understand maybe using a perfect manufacturing technique to produce a stable epoxy result with glass etc, but not diy.

there seems to be 4 major costs in a diy panel, the cells, the glass and frame, the encapsulant, the rest (tabbing and bus wire, solder, flux, junction box, diodes and cables) spend about the same amount on each and you will have a decent diy panel if you can put the recipe together, am about $2 per watt. for glass and frame am using recycled sliding doors which has saved alotLeave a comment:

-

check out with this guy did...he used silicon caulk.

make a post in the thread (the one i'm linking below) if you have a question and he'll get the message, if not i'll write him personally

Here's the thread

http://www.solarpaneltalk.com/showth...ight=jestronixLeave a comment:

-

never mind the misting part..lets concentrate on sealing the PV's

Any alternate to expensive sealers..they are basically the sole culprit of driving cost high..I shall look into methods of preserving the sealer compound minimizing the quantity needed per panel may be?Leave a comment:

-

Unless you mist with distilled water, you will bake on dirt and minerals. Best to not bother with this idea, unless you are really set on it.

Cells need a hermetic seal to prevent internal corrosion, if you think you have a method, build one now, and get it out in the weather so you can start debugging it. Few materials can provide a water VAPOR seal that is needed.

Consider some of the blems or non-UL panelsLeave a comment:

-

low cost encapsulation

I am working on a "proof of concept" solar power solution for a very very poor community of a poor country and ran into trouble of keeping cells well encapsulated. Since cost is a very big factor here therefore no question of exotic sealants like PV-804 or Sylgard-184.

Instead I was thinking to sandwich the solar cell array in UV / Weather Resistant heat shrink film and toss it in the oven. Designing the panels to be reclaimable and repairable in future is also important due to high occurrence of stray bullets flying overhead. Couple that with poverty and a damage to single panel could mean a big loss for an individual.

Can someone with experience assist me with their valuable opinion I shall be grateful for life.

I can also couple an automated misting system triggered by surface temperature to keep the panels cooler in extreme summer heat.Leave a comment:

-

rather than try suggest alternatives at this point i would like to see your experiments with EVA and the rest. have wondered how to get the air out with diy vacuums. have some experience with the liquid encapsulants like sylgard but would like to know more about diy EVALeave a comment:

-

Moisture proofing panels, which is better, EVA, Slygard 184, venting or sealing?

I am left just wondering what and how to protect the thin 6x6 cells that I plan on putting in to a DIY panel. I have bought EVA film and Tyvek tape and was thinking I would heat seal the EVA on tempered glass, use the tape to seal the edges of the glass and back panel and possibly even try to vacuum out the air space sealing the holes in the frame with "something" as I have read that silicon sealant will not keep out moisture vapor. Now, reading that possible venting will keep cell damage from happening, just makes me wonder: just what do I need to do? Am not concerned with cost as I am only building one panel to take to remote camping sites. So, which approach is best, seal or not seal? And if the panel is vented, does that mean the cells are just left unsealed against the front glass panel? The more I read, more I am confused.Leave a comment:

-

The don't need to be air tight, but they need to be moisture proof. If you can seal them 100% or vent them 100%, so that you never get condensation in them, you are good. Any condensing moisture will quickly ruin the solar cells, and you panel will die.

Painted wood, silicone seal, epoxies and most plastics, are not water vapor proof, and you will get condensation inside eventually.Leave a comment:

-

Yes they should be air tight , any space can cause moister , and if you spent anything at all for your panel it's worth to do it right to protec it.Leave a comment:

-

Air tight panel?

Do all panels need to be air tight? forgive my ignorance, i am so new that I have materials sitting at my house (i'm in Iraq) waiting for me that I haven't seen yet.Leave a comment:

-

Right. You should try out on a pc of wood first in a very small app. Sorry about that.Leave a comment:

-

I contacted a company in the states called Epic Resins and asked about an Epoxy for solar cells, after a couple of discussions over the phone and an in person meeting with the area rep, they agreed to send me a free sample of a Polyurethane 2 part epoxy. It arrived a few weeks later and I mixed it up according to the Data sheets and a digital scale. I must of did something wrong, because after 3 weeks of low humidity, it never hardened. I actually had to throw out an entire 36 cell panel. It looked just like slime. Too bad, my bad. Should of tried it out on a smaller panel.Leave a comment:

-

Do you know if your epoxy has any UV resistance? Generally, epoxy will yellow and degrade over time if exposed to UV.Leave a comment:

Copyright © 2014 SolarReviews All rights reserved.

Powered by vBulletin® Version 6.1.3

Copyright © 2026 MH Sub I, LLC dba vBulletin. All rights reserved.

Copyright © 2026 MH Sub I, LLC dba vBulletin. All rights reserved.

All times are GMT-5. This page was generated at 10:41 AM.

Leave a comment: