Nice detailed illustrations there. Perhaps they help to see that in either mode that system volumes are fixed and equal...no gross difference in system volume when mode cycles.

Liquid lines always move liquid and gas or vapor lines always move gas...reversing valve handles the mode cycles..compressor within never changes flow direction.

Try our solar cost and savings calculator

Any experience with a DC-powered mini-split air conditioner?

Collapse

X

-

Thanks, more study material. If that compressor is 3 phase, reversing it would be easy. There"Central" heat pumps use a reversing valve as described in the above link (and yes, it does CLANK); I haven't opened a mini-split to see what happens in there--but I'm pretty sure it doesn't run the compressor backwards for heat mode (like I read someone insisting elsewhere. Wonder if their car runs the internal combustion engine backwards when they want to reverse, too!)

have been vehicles built that reverse their engines to back up, starting with locomotives.

Bruce RoeLeave a comment:

-

Here's a simple yet concise explanation of how a heat pump works: http://www.refrigerationbasics.com/R...eat_pumps1.htm

"Central" heat pumps use a reversing valve as described in the above link (and yes, it does CLANK); I haven't opened a mini-split to see what happens in there--but I'm pretty sure it doesn't run the compressor backwards for heat mode (like I read someone insisting elsewhere. Wonder if their car runs the internal combustion engine backwards when they want to reverse, too!)Leave a comment:

-

I am waiting for an explanation of just how the reversing valve and the rest manage

to turn the system around, with coils and pipes still in place. I could certainly hear

that valve CLANK when my older equipment needed to defrost itself. Not so on the

mini split, though I might have detected cooling when it was set for heat. Bruce RoeLeave a comment:

-

Wrong terminology. I'm not a HVAC tech. When I said 'condenser' I meant 'outdoor unit'; Am I correct that when heating the phase change occurs in the outdoor unit? Not arguing... just curious.Leave a comment:

-

Not disagreeing with you about refrigerant volumes being precise, in these pre-charged units, don't care to argue that with you.

I do take exception with your misinformation in refrigerant circuits...don't claim your victory on misinformation there.Leave a comment:

-

Exactly. So the 'right' amount of refrigerant needed is going to vary A LOT depending how how many indoor units are in use and whether it's cooling or heating => 'precision' on how much refrigerant is in the unit is irrelevant... you just need to have enough.

If a unit comes pre-charged for up to 110' of line and your lines are only 10' there's no efficiency benefit to removing refrigerant.Leave a comment:

-

Okay, Thanks for adding your success stories,

Wouldn't the phase change start at the expansion valve outlet near the reversing valve and the compressor?

The reversing valve changes the role of condenser and evaporator back and forth...Last edited by neweclipse; 07-01-2019, 03:30 PM.Leave a comment:

-

Even in heating mode? I think the liquid line is too warm for liquid refrigerant in heating mode. Pretty sure the phase change happens in the condenser when in heating mode.

But... even beyond that... there would need to be an allowance for how many indoor units are in operation. The shutoff valves for the indoor unit is located in the condenser so the amount of liquid refrigerant in lines would vary depending on how many are in use. The amount of refrigerant in the unit doesn't need to be exact... just enough for operation. I've DIY'd 4 mini-splits. I just used to the included refrigerant and they're all doing great. It's super-easy. You just need a vacuum pump and a gauge set which I think you can find now for <$400.

Last edited by nwdiver; 07-01-2019, 02:17 PM.Leave a comment:

-

Yeah, but, your way of thinking leaves out the all important 3 way reversing valve...otherwise you might of had it correct...

The tolerance for refrigerant loading would have to be very wide for it to be able to operate in cooling and heating mode. When it's cooling the line set has liquid in it. When it's heating it has gas in it. So the volume of refrigerant will shift A LOT depending on mode. Most mini-splits I've seen come with a certain pre-charge and that charge is good for up to usually ~115' or so. I doubt there's any benefit to efficiency to removing some refrigerant if you're only running 20' of line.

Liquid line always has liquid in it and gaseous line always has gas in it when in operation.Last edited by neweclipse; 07-01-2019, 01:25 PM.Leave a comment:

-

The tolerance for refrigerant loading would have to be very wide for it to be able to operate in cooling and heating mode. When it's cooling the line set has liquid in it. When it's heating it has gas in it. So the volume of refrigerant will shift A LOT depending on mode. Most mini-splits I've seen come with a certain pre-charge and that charge is good for up to usually ~115' or so. I doubt there's any benefit to efficiency to removing some refrigerant if you're only running 20' of line.

Leave a comment:

-

Thanks for doing the arithmetic. A C. O. P. approaching 4 is pretty good.

I expect there is rather minimal energy loss in the input section, whether it is a

rectifier, a DC-DC converter, or an MPPT panel input, so that factor would not

give one system a big advantage over another. That thanks to solid state

advances in recent decades. Massive heat sinks of earlier times are minimal

now. Bruce Roe

Leave a comment:

-

You're completely right. However, I was trying to establish worst-case scenario, and determine A/C efficiency.

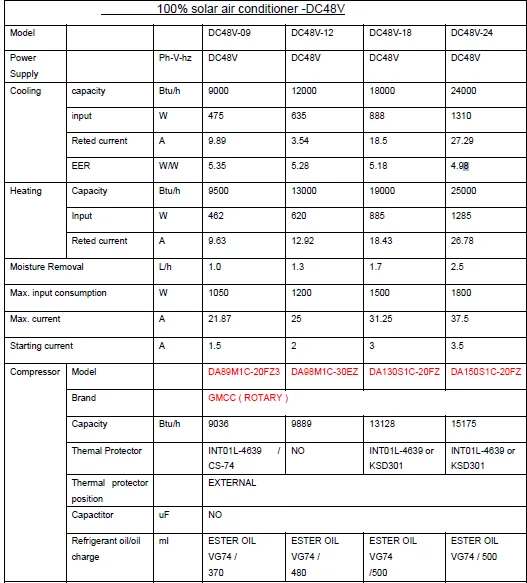

It's China...they can be known to overstate things (like those 9,900mAH 18650 Li-ION cells--talk about an off-gridder's powerwall dream! Until you buy them and are lucky to get 900mAH out of them.) The problem in this case is that the EER (W/W) is stated as 5.58 (if it was BTU-H/W it would be 20 EER). They list 18000BTU as 5,000W of work (mathematically it equates to 5,275W). And 5,000W / 5.58 EER = 896W input power. As shown in the specs below:

EDIT: can't upload tables. Ended up with just a partial post, and HTML displayed. Grr...maybe I can copy-paste a picture (NOTE THAT THIS IS FROM A DIFFERENT LISTING, shows EER OF 5.18 on the 18000BTU unit).

Basically, if I take the updated 1,400W for 18,000BTU output, that gives me an EER (BTU-H/W) of only 12.8, or very close to a 220vAC mini-split (when NOT figuring in inverter losses). So much for the "holy grail"...Last edited by NochiLife; 07-01-2019, 11:29 AM.Leave a comment:

-

1400 W sounds about like a possible running power draw.

(18,000)/((3.412)*(1400)) = 3.76 ~ a reasonable est. for a running C.O.P. in cooling mode.Leave a comment:

-

That may be the peak you must allow for. But average over time will vary greatly

with the actual thermal loading, could easily be half or less. Bruce RoeLeave a comment:

Copyright © 2014 SolarReviews All rights reserved.

Powered by vBulletin® Version 6.1.3

Copyright © 2026 MH Sub I, LLC dba vBulletin. All rights reserved.

Copyright © 2026 MH Sub I, LLC dba vBulletin. All rights reserved.

All times are GMT-5. This page was generated at 04:30 AM.

Leave a comment: