All wrong again Simon. Maybe in your country LFP make sence, but that is because you do not have access to quality made batteries at reasonable price points. Your stupid government energy policies and taxes prevents you from access. You get Chi-Coms, the stuff you sell to suckers. Quit denying it or I will post your full name, email address and your company web site. You are easy to find, and wreckless on the web.

In the USA top of the line 5 to 10 year Pb battery cost 20-cents per watt hour. 1 to 2 year Chi-Coms like you own, sell , and advocate cost 40 to 50-cents per watt hour. There is no comparison. Even with the smaller LFP requirement of 3/5 of Pb at end of lifetime still cost 200 to 400% more than Pb.

When it comes to cost justification, EV's are on eof the few that can justify the cost of Lithium Batteries. None use Chi-Com or LFP batteries. The public has no access to quality Lithium batteries other than Salvage operations from a wrecked EV which is where I got mine.

LifePO4 GBS Amp Hour Testing 2.5v to 3.6v per cell

Collapse

X

-

Last edited by Sunking; 08-17-2016, 06:15 PM. -

Leave a comment:

-

You just proved you are as clueless and dangerous as DAX. You have no clue what Ohm';s Law is

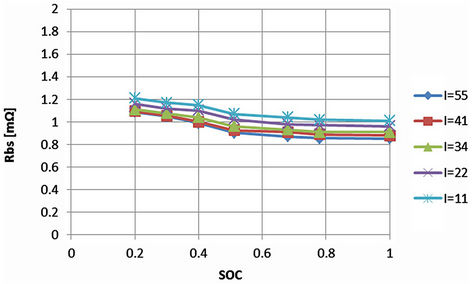

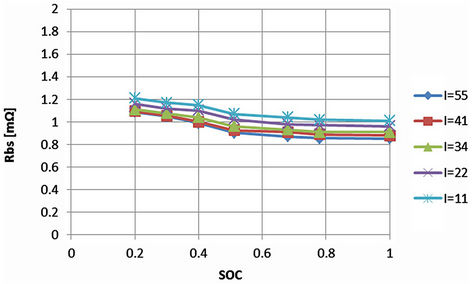

Can you please give some references to back up your argument about Internal Resistance vs SOC. I found this graph for LFP batteries from file.scirp.org/Html/11-6201413_25079.htm

The reason that lead acid batteries will pass current through them if you raise the voltage high enough is that you start breaking down the water in the electrolyte to hydrogen and oxygen. This is a side reaction within the battery.

It is the cell voltage that goes up when the LFP battery is full. The battery will only get hot if you are charging it at high charge rates. If you charge it at a very low charge rate when the battery is full the voltage will rise but it will not get hotter until you reach a voltage of around 4.5V at which point you will start breaking down the electrolyte, this will generate heat. Rather like the water being broken down in the lead acid battery.

Simon

It all has to do with Internal Resistance. If you really knew your stuff, you would know if you look at any charge/discharge curves every manufacture publishes gives the Ri in graphical form The Ri Curve is identical charge/discharge voltage curve. It is simple Ohm's Law and you can calculate Ri from any discharge curve. They are hiding in the math you cannot see or understand. Those Knees of the curve are direct result of the Ri changes. Voltage and Resistance controls current flow, not SOC. Any student of the trade can tell you that.Last edited by Sunking; 08-17-2016, 05:55 PM.Leave a comment:

-

Wrong again Simon, and you cannot keep your story straight. One minute Voltage sag is not a problem, and the next it is real. Make up your mind. Simple physics.

You are speaking of Specific Power which i know you have no clue what that means because if you did, you would know you just stuck your foot in your mouth and proved you do not know much.

Specific Power or gravimetric power density, indicates loading capability expressed in W/Kg. Picture says it all. Cheap Chi-Coms run the low on the graph. However that does not tell the whole story because that is weight for weight comparison, not capacity to capacity. If we take a 100 AH Chi Com @ 12 volts we have a 12 Kg battery and a Pb of equal capacity and voltage would weigh in 50 Kg. The LFP would have to have 4 times the Specific Power to equal a Pb battery. So when it comes right down to it Ah per AH, Pb is equal to Specific Power. No gain.

Its all about application and find the right battery for the job. You are a 1-trick pony who really does not know much.

Give you a Clue Simon. Specific Power is Directly related to Internal Resistance. Another Clue many AGM batteries are deigned to be discharged in 15 minutes. and Forklift and Golf Cart batteries are made for 10C. Its the application one trick pony. Just about any AGM battery is equal to or better than any Chi-Com with respect to Specific Power. Any decent AGM, Telecom AGM/FLA, or Traction AGM/FLA is superior and any Traction FLA/AGM will last longer than Chi-Com LFP and less expensive.Last edited by Sunking; 08-17-2016, 05:48 PM.Leave a comment:

-

I can think of a few other advantages of LFP over Pb, how aboutNot to worry, all of it is manageable. Only thing that cannot be managed today is economics. Today Pb batteries are king of economics and performance. Until lithium battery prices fall to equal or less than PB, then Pb will dominate. The only huge advantage lithium has, energy density, is not required or can be justified for most off-grid systems. One exception I can think of is RV or Boat where weight and space come at premiums.- Higher charge acceptance right up to 100%SOC. Means you can charge at 0.5C with a very small absorb time.

- Very high efficiency, around 95% power efficiency

- Very flexible charge parameters, basically from 0A to 0.5C. None of this having to charge at around 0.1C

- No voltage sag on high discharge current over a period of time, peukert coefficient close to 1

- Zero maintenance if BMS if fully automated

- Ability to utilise 80%-90% of the battery capacity on a regular basis

- Ability to accurately calculate to within a few percent the amount of power left in your battery.

- Ability to leave battery partially full for an extended period of time with no detriment to the battery

You are wrong about cost, LFP batteries come out around the same if not better if you compare them on a cost per kWh cycled through the battery.

Simon

Leave a comment:

-

Can you please give some references to back up your argument about Internal Resistance vs SOC. I found this graph for LFP batteries from file.scirp.org/Html/11-6201413_25079.htm

The reason that lead acid batteries will pass current through them if you raise the voltage high enough is that you start breaking down the water in the electrolyte to hydrogen and oxygen. This is a side reaction within the battery.Very desirable but gives us a challenge when charging. Unlike eall other batteries can tolerate excessive over charging. In fact we use that ability. With a Lead Acid battery when one gets fully charged up its resistance is at it lowest and passes current down to lower level batteries thus EQUALIZING them.

Not Lithium, current stops when a Lithium cell is Saturated and fully charged up. Its resistance shoots up to stop current flow. If you force it with higher voltage is converted directly as heat. More heat, more current. Thermal Run-Away.

It is the cell voltage that goes up when the LFP battery is full. The battery will only get hot if you are charging it at high charge rates. If you charge it at a very low charge rate when the battery is full the voltage will rise but it will not get hotter until you reach a voltage of around 4.5V at which point you will start breaking down the electrolyte, this will generate heat. Rather like the water being broken down in the lead acid battery.

Simon

Leave a comment:

-

Dax has stated that the cable length from the battery to the inverter is 30cm(1ft), so his cable cost is $12. Hardly a major issue. I am sure his company could afford the appropriate tools. You have no idea whether Dax has the capability or hires someone with the capability to terminate the cables properly.3000 watts / 12 volts / .85 eff = 295 amps moron. Math does not lie, only HACKS and FRAUDS lie. In the USA that would require a minimum 3/0 copper cable to be SAFE, Very very expensive copper cable of $6 per foot. In Aus that is equivalent to 11mm or 85mm^2 copper cable.

No one in their right mind who knows anything about power would use 12 volts on a 3 Kw inverter. Not only is it extremely dangerous, but extremely expensive requiring special tooling I know you do not know about to terminate such large cables. 3 Kw demands 48 volt minimum.

I have a 24V 4kW inverter, Bala has a 24V 3kW inverter and I am sure there are lots more people like us. Peak recorded current from my battery is 245A. Normal heavy load is ~150A and normal load ~5A. Has not burnt the house down yet. The company that made my inverter is over 10 years old and is still in business so must be doing something correctly. Having lead acid batteries is one of the main reasons for not having an inverter with a high current draw as they don't cope with high currents for any length of time. The classic Lead acid battery voltage sag.

SimonLeave a comment:

-

For all the engineering and high tech stuff in a Tesla car, they still fault and catch fire:

-------------- Date: Tue, 16 Aug 2016 07:48:04 -0500 From: "Alister Wm Macintyre " Subject: Tesla Spontaneously Catches Fire! Tesla Spontaneously Catches Fire, Burns Down During Test Drive In France. Not yet explained. There are some clues. http://www.zerohedge.com/news/2016-0...t-drive-france

https://electrek.co/2016/08/15/tesla...-drive-france/

http://bgr.com/2016/08/15/tesla-mode...os-test-drive/

https://www.reddit.com/r/teslamotors...test/?sort=top Earlier there was a Tesla on fire in Norway. A short circuit is the explanation. An automobile spontaneously catching on fire, is not a risk unique to Tesla. Many other auto brand names also experience this surprise hazard. http://www.teslarati.com/tesla-short...s-norway-fire/

http://www.vg.no/forbruker/bil-baat-...or/a/23640710/

--------------Leave a comment:

-

The article you posted is about dendrite growth on lithium anodes, all the main lithium ion technologies around at the moment use carbon as the anode to get around this problem. You can get dendrite growth on carbon anodes, it is a result of extended exposure to voltages above 3.65V/cell not cycling.Yeah, that's for sure...as I've been reading about the dendrite stuff, I saw one study[1] that thinks that the dendrites are actually the result of impurities in the lithium, and there are a ton of thoughts about what additives could be, well, added, to help prevent it as well.

All I can say is there are a lot of lucky people around then, just go and look on the Energy Matters and the Endless Spheres forumsSo yeah, time will tell about that, as well as about whether folks with awesome cycle and calendar life are just lucky, or on the cutting edge for the next big thing.

Simon

Leave a comment:

-

Uhh. Isn't that like kicking a dead horse since he has been banned?

You are a Fraud, Hack, and Pretender. You just proved it again. This time was so obvious this others caught it. I spotted you a long time ago when Karrak drug you over to attack me. A 3 Kw inverter operating at 12 volts would draw 300 amps. Up to 600 amps on large motor loads. If you knew Ohm's Law (5th grade math) and efficiency you would know that. Here is proof everyone but Dax will understand. It is simple 5th grade math:

Amp = Watt / Volt / Efficiency Factor of System

3000 watts / 12 volts / .85 eff = 295 amps moron. Math does not lie, only HACKS and FRAUDS lie. In the USA that would require a minimum 3/0 copper cable to be SAFE, Very very expensive copper cable of $6 per foot. In Aus that is equivalent to 11mm or 85mm^2 copper cable. However used the way you use it over long distances would not work if you tried to pull 3000 watts or 300 amps, not even 100 amps from the batteries. 3/0 can only supply 300 amps up to 5-feet one-way before voltage loss became so severe the inverter would trip off line from under voltage. Just to get 25-feet one way would require 750 MCM copper cable. That cost $15/foot and a 750 MCM is the size of a Man,s wrist and weighs 8-pounds per foot. That is only cable voltage loss, the battery loss will be higher at 6% voltage loss.

No one in their right mind who knows anything about power would use 12 volts on a 3 Kw inverter. Not only is it extremely dangerous, but extremely expensive requiring special tooling I know you do not know about to terminate such large cables. 3 Kw demands 48 volt minimum. Commercial systems even know this, you will not find a commercial battery system less than 100 volt battery. 300 to 500 volts being common. At 300 volts a 3 Kw Inverter is only 10 amps on real small wire ran across the house

My advice to you is shut up. Because every time you give any details, you give us rope to hang you with. It clearly demonstrates you have no knowledge of what you are doing or why. Batteries and power does not even remotely work like you think it works. It is very simple MATH, and YOU DO NOT ADD UP correctly.

Leave a comment:

-

No that is just one of many Failure Mechanisms. Lithium batteries are sensitive and fickel compared to all other batteries. They are not Robust as Pb and Nickel chemistry. They do not play well in hot or cold environments (getting better with LMO), will not tolerate any over discharge, and very sensitive and dangerous to over charge. Other than that and cell voltages they are no different than any other battery.One thing that's been nagging me (and my ignorance of lithium batteries from a chemical standpoint) is -- isn't the main degradation with lithium-based batteries connected to dendrite growth from charge/discharge cycles? If that's the case, how does micro-cycling batteries affect that?

Let's get to it. What you want to know. How do I treat my batteries and not kill them. Ignorance is the number 1 killer of Lithium batteries. Heat issues are the most probable cause of premature failure followed by external elements like short circuits, or faulty equipment.

If what the scientist and manufactures were true, lithium ion batteries would last forever if it was only an electrical charge and not chemical. Fact is there is chemical reactions, and it is caused by HEAT. The electrolyte inside is Organic Solvents. Guess what happens to organic material when heated up? It decays. When that happens internal resistance builds up making the battery useless.

Good news in a home off-grid battery system, Heat is NOT a big issues, and in most applications not a factor. If they are installed where n temps stay above 40 and below 100 out of the sun with ventilation is OK. EV's are another story.

Another way to over heat batteries is with high charge or discharge rates. By HIGH I mean 1C or more. Well if your system is properly designed and sized, you are never going to push 1C for any meaningful time. How many of you plan to use 3 days of electricity in 30 minutes? In a properly sized system you would be charging at C/2 or less. On discharge more like C/10 on PEAK LOADS briefly, otherwise less than C/20. So charge/discharge heat is not much of an issue for most off-grid applications.

Now here is where it can be a problem. Over Charge: This is where you need to educate yourself and prevent over charge. Good news is if you are using LiFeP04 aka LFP is the most Tolerant to over charge in the Lithium family. They are the safest of all the lithium batteries.

A unique characteristic of lithium batteries is there Internal Resistance vc SOC curve. It is reverse of all other batteries. As it charges up, its internal resistance goes UP. Very desirable but gives us a challenge when charging. Unlike eall other batteries can tolerate excessive over charging. In fact we use that ability. With a Lead Acid battery when one gets fully charged up its resistance is at it lowest and passes current down to lower level batteries thus EQUALIZING them.

Not Lithium, current stops when a Lithium cell is Saturated and fully charged up. Its resistance shoots up to stop current flow. If you force it with higher voltage is converted directly as heat. More heat, more current. Thermal Run-Away.

The other failure mode is very common among DIY and easy to do especially if you use Balance Boards and rely on automation to do your job. OVER DISCHARGE. LFP will not Tolerate OVER DISCHARGE. It is instant death. Easy to prevent.

Not to worry, all of it is manageable. Only thing that cannot be managed today is economics. Today Pb batteries are king of economics and performance. Until lithium battery prices fall to equal or less than PB, then Pb will dominate. The only huge advantage lithium has, energy density, is not required or can be justified for most off-grid systems. One exception I can think of is RV or Boat where weight and space come at premiums.Last edited by Sunking; 08-16-2016, 05:24 PM.Leave a comment:

-

See we agree sometimes.If it never draws 275 amps it's not being used as a 3kW inverter. If you install a 3kW inverter and downrate it to 1.6kW, great - but in that case might as well just install a good 1.6kW inverter.

No, that doesn't mean that. 120V and 240V inverters are readily available with a wide variety of mounting options.

The more you post, the more it sounds like your success has been due to luck rather than technical competence and an understanding of the issues involved.. I hope for the sake of your customers that your luck doesn't run out.Last edited by Sunking; 08-16-2016, 04:30 PM.Leave a comment:

-

You are a Fraud, Hack, and Pretender. You just proved it again. This time was so obvious this others caught it. I spotted you a long time ago when Karrak drug you over to attack me. A 3 Kw inverter operating at 12 volts would draw 300 amps. Up to 600 amps on large motor loads. If you knew Ohm's Law (5th grade math) and efficiency you would know that. Here is proof everyone but Dax will understand. It is simple 5th grade math:

Amp = Watt / Volt / Efficiency Factor of System

3000 watts / 12 volts / .85 eff = 295 amps moron. Math does not lie, only HACKS and FRAUDS lie. In the USA that would require a minimum 3/0 copper cable to be SAFE, Very very expensive copper cable of $6 per foot. In Aus that is equivalent to 11mm or 85mm^2 copper cable. However used the way you use it over long distances would not work if you tried to pull 3000 watts or 300 amps, not even 100 amps from the batteries. 3/0 can only supply 300 amps up to 5-feet one-way before voltage loss became so severe the inverter would trip off line from under voltage. Just to get 25-feet one way would require 750 MCM copper cable. That cost $15/foot and a 750 MCM is the size of a Man,s wrist and weighs 8-pounds per foot. That is only cable voltage loss, the battery loss will be higher at 6% voltage loss.

No one in their right mind who knows anything about power would use 12 volts on a 3 Kw inverter. Not only is it extremely dangerous, but extremely expensive requiring special tooling I know you do not know about to terminate such large cables. 3 Kw demands 48 volt minimum. Commercial systems even know this, you will not find a commercial battery system less than 100 volt battery. 300 to 500 volts being common. At 300 volts a 3 Kw Inverter is only 10 amps on real small wire ran across the house

My advice to you is shut up. Because every time you give any details, you give us rope to hang you with. It clearly demonstrates you have no knowledge of what you are doing or why. Batteries and power does not even remotely work like you think it works. It is very simple MATH, and YOU DO NOT ADD UP correctly.Last edited by Sunking; 08-16-2016, 04:17 PM.Leave a comment:

-

Dax is gone. Yeah!

Was a good move Mike, he was a hack and could get someone seriously hurt and the owners could find themselves in court for letting that moron participate.

Last edited by Sunking; 08-16-2016, 04:30 PM.

Last edited by Sunking; 08-16-2016, 04:30 PM.Leave a comment:

-

Yeah, that's for sure...as I've been reading about the dendrite stuff, I saw one study[1] that thinks that the dendrites are actually the result of impurities in the lithium, and there are a ton of thoughts about what additives could be, well, added, to help prevent it as well.

So yeah, time will tell about that, as well as about whether folks with awesome cycle and calendar life are just lucky, or on the cutting edge for the next big thing.

[1] http://phys.org/news/2013-12-view-de...ries-root.htmlLeave a comment:

Leave a comment: